Natural Gas Pipe Sizing High Pressure

Natural gas travels from wellheads to end consumers through a series of pipelines. These pipelines—including flowlines, gathering lines, transmission lines, distribution lines, and service lines—carry gas at varying rates of pressure. The higher the pressure of gas in a pipeline, the more potentially dangerous an accident with that pipeline could be.

Z You can assume that each cubic foot of natural gas releases 1,000 Btu per hour. Some gas has Btu ratings that vary slightly, but 1,000 Btu per cubic foot is generally a safe assumption. Assume you’re sizing pipe for a gas range with a maximum demand of 68,000 Btu per hour. Divide the value in Btu by 1,000 to find the demand in cubic feet. Where a diversity of load can be established, pipe sizing shall be permitted to be based on such loads. The volumetric flow rate of gas to be provided shall be adjusted for altitude where the installation is above 2,000 feet (610 m) in elevation. 402.3 Sizing. Gas piping shall be sized in accordance with one of the following. A pipeline system needs to consider not only the velocity but also the pressure drop in the pipeline. This is specifically true when we are talking of long distance sales gas (natural gas) transmission pipelines and the required pressure at the terminal end of the pipeline governs the line size along with the velocity.

Pipelines usually are buried underground, and pipeline markers do not always sit directly above the pipelines.

Flowlines

Flowlines connect to a single wellhead in a producing field. Flowlines move natural gas from a wellhead to nearby storage tanks, transmission compressor stations, or processing plant booster stations. Flowlines are relatively narrow pipes that carry unodorized raw gas at a pressure of approximately 250 pounds per square inch (psi).

Typically, they are buried 4 feet underground and can corrode, especially if they are carrying wet gas. They also are prone to methane leakage. According to the EPA, 'methane leakage from flowlines is one of the largest sources of emissions in the gas industry.'

Gathering Lines

Gathering lines collect gas from multiple flowlines and move it to centralized points, such as processing facilities, tanks, or marine docks. Gathering lines are medium steel pipes (usually less than 18 inches in diameter) that carry unodorized, raw gas at a pressure of approximately 715 psi.

Typically, gathering lines are buried 4 feet underground and carry corrosive content that can affect pipeline integrity within a few years.

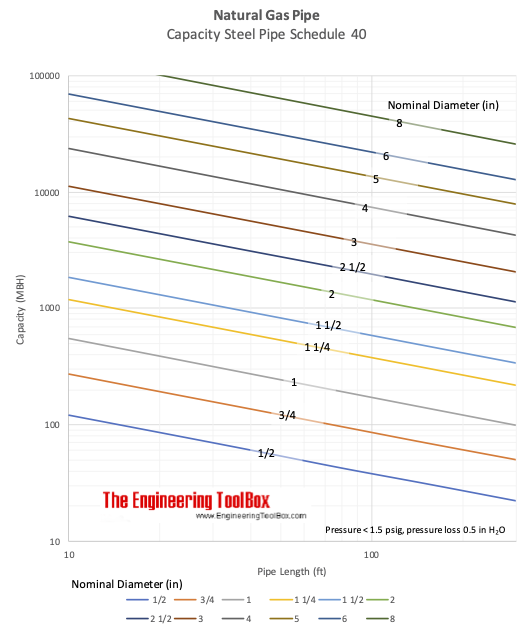

High Pressure Gas Sizing Chart

Transmission Pipelines

Transmission pipelines carry natural gas across long distances and occasionally across state boundaries, usually to and from compressors or to a distribution center or storage facility. Transmission lines are large steel pipes (usually 2 to 42 inches in diameter; most often more than 10 inches in diameter) that are federally regulated. They carry unodorized gas at a pressure of approximately 200 to 1,200 psi.

How to mod hearts of iron 4. Transmission pipelines can fail due to seam failures, corrosion, materials failure, and defective welding.

Distribution Pipelines

Distribution pipelines, also known as 'mains,' are the middle step between high-pressure transmission lines and low-pressure service lines. Distribution pipelines operate at an intermediate pressure. This type of pipeline uses small to medium pipes (2 inches to 24 inches in diameter) that are federally regulated and carry odorized gas at varying pressure levels, from as little as 0.3 psi up to 200 psi.

Distribution pipelines typically operate below their carrying capacity and are made from a variety of materials, including steel, cast iron, plastic, and occasionally copper.

Service Pipelines

Service pipelines connect to a meter that delivers natural gas to individual customers. Service pipelines are narrow pipes (usually less than 2 inches in diameter) that carry odorized gas at low pressures, such as 6 psi. Service pipelines typically are made from plastic, steel, or copper.

Calling 811

Every state in the U.S. has an 811 call center that provides varying amounts of information about the location of utility lines, including gas pipelines. If you are planning any sort of project that involves digging into your property, it is highly recommended that you use this service or otherwise identify the location of gas pipelines and other utility lines on your property. Utility companies typically will mark your property within a few days after you call, so make sure you place the call well in advance of when you plan to dig.

Even small projects, such as installing fence posts, can lead to trouble if homeowners proceed without knowing what might be beneath the location where they are digging. Learn about demolishing methods while you're at it.

The Gas Pipe Sizing Calculator is an extremely easy to use app that will help you to select the right size pipes for installations using copper (up to 108mm), steel (up to 300mm) and PE (up to 315mm) pipes of sections up to 250m (820ft) in length.

To carry out a calculation simply select the gas type, enter the appliance heat input, enter the pipe length, the number of high or low loss fittings (guidance is given in the app), select the type of pipe and then press the 'Calculate' button.

The results will show the total equivalent length, the minimum pipe diameter (metric) that should be used and the pressure drop for that section of pipe.

For multiple appliances each section should be calculated in turn and the kW inputs for the appliances in each section added together for each calculation.

The maximum pressure drop from each appliance to the meter should be no more than 1 mbar for natural gas or 2.5 mbar for butane or propane. Adding all drops together using the minimum pipe diameters may cause this to be exceeded. Where possible, the results will also calculate the drop if the next larger size pipe diameter is selected on a section, this should help to ensure the right sizes are used throughout the whole circuit.

Please note: This app is designed mainly for the UK so supports metric pipe sizes only.